美国 Heller Industries

Mark 7 Series - Reflow Oven

Latest Low Height Top Design

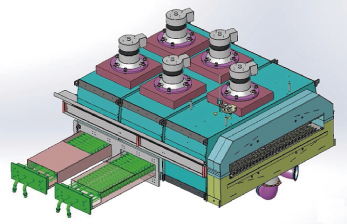

MK7 adopts the latest low height top design for ease of customers’ operations and maintenance, lower mechanical surface humidity, good at environmental protection and energy saving.

|

Revolutionary Flux Management System |

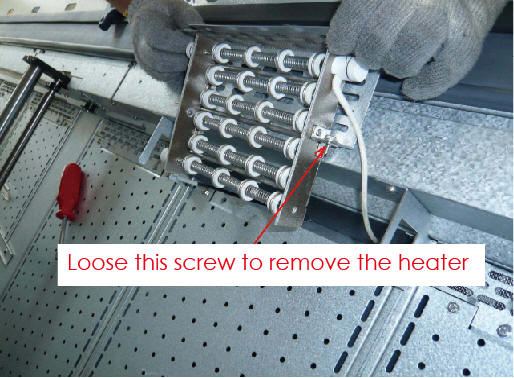

Optimized New Heating Module

|

|

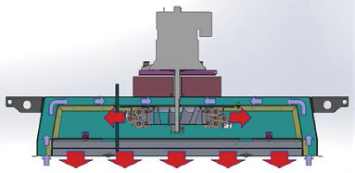

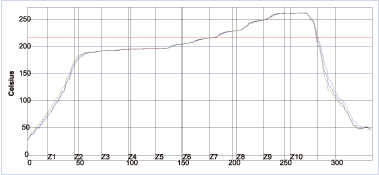

Flexible Cooling Rate Slope

|

|

|

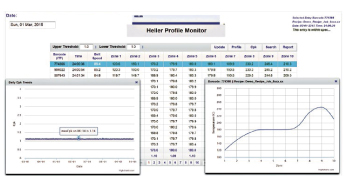

Reflow Oven CPK – Real Time Process Parameter Monitoring A dynamic 3-tiered system Tier 1:Reflow Oven CPK Tier 2:Process CPK Tier 3:Product Traceability

|

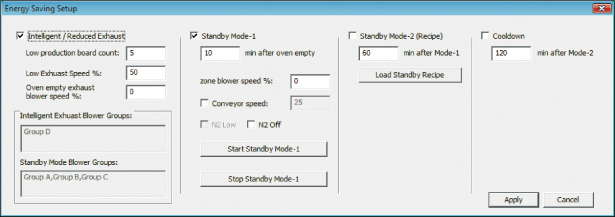

Reflow Oven Energy Management Software

|

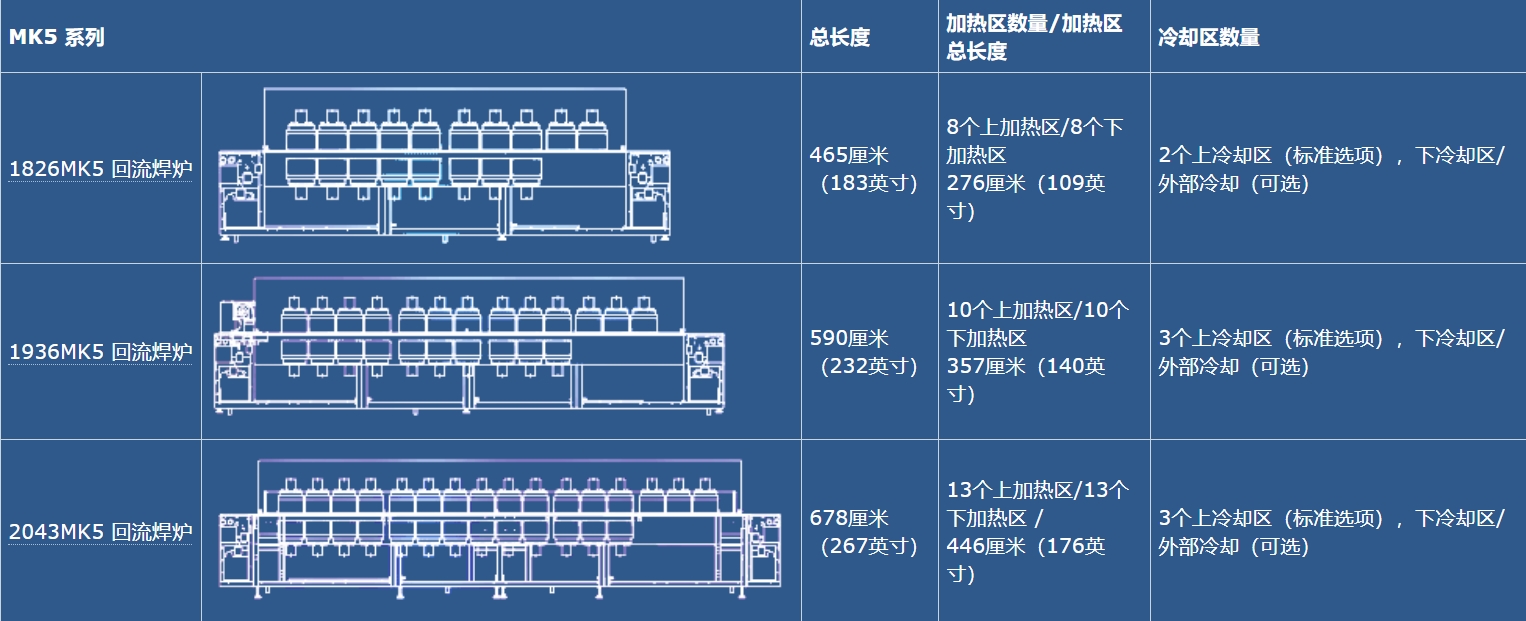

Reflow Soldering Ovens - Mark 5 Series

|

These reflow oven workhorses provide consistent performance for high volume requirements while minimizing preventative maintenance and floorspace. The latest breakthroughs associated with the Mark 5 convection reflow oven now provide you with an even lower cost-of-ownership. Heller’s new heating and cooling advances deliver up to 40% reduction in nitrogen and electrical consumption. This makes the MK 5 system not only the premier reflow soldering system but overall the best convection reflow oven value in the industry!

• New Cool Pipe Flux System Virtually Eliminates Maintenance • Lead Free Certified • Lowest Nitrogen & Electrical Usage • Integrated Cpk software • Enhanced Heater Modules • Fastest Cooling Rates • One-Step Profiling

|

The ultimate high volume production solutions with belt speeds up to 1.4 m/min to accommodate the fastest pick and place systems. The MK5 reflow oven systems deliver the highest levels of repeatability with the lowest delta Ts. The latest breakthroughs associated with the Mark 5 reflow system now provide you with an even lower cost-of-ownership. This reflow oven’s new heating and cooling advances deliver up to a 40% reduction in nitrogen and electrical consumption. This makes our reflow oven system not only the premier reflow soldering system but the best overall value in the industry!

|

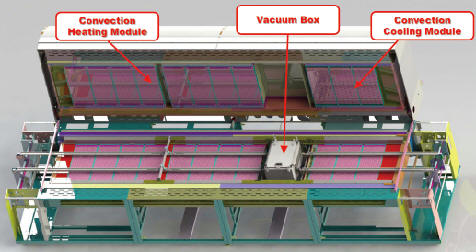

Advanced In-Line Vacuum Reflow Oven

Nitrogen System with Balanced Flow Technology

- 9 Top And Bottom Heated Zones - highest zone count per linear foot in the industry!

- 100" Heated Length - for super throughput!

- 2 Internal Cooling Zones - gives lowest exit temperature!

- 180" Total Length - optimizes floorspace utilization!

- NEW Module Design with 10" modules gives the flexibility to subdivide the profile into smaller segments and allows for more refined "profile sculpting". The only way to satisfy demanding Lead Free Applications!

- Reflow zones configured for Lead Free Soldering as well as Eutectic requirements.

- Nitrogen Inert Atmosphere To 10 PPM with 50% reduction in N2 consumption !

- AWARD WINNING Flux Separation System

- Fitlerless Flux Separation System

- Water Cooling Option To Increase Cooling Rate

- "Easy Clean" Mode That Only Takes 30 Minutes

- Oxygen Monitoring With Closed Loop Control for tightest process control!

- Oven Cpk Reporting Software - Powered by ECD, this SPC package gives real time Cpk info on your process - A STANDARD FEATURE at No additional charge!

真空辅助回流炉图示

Horizontal Convection Fluxless Reflow Oven

Heller has designed and built an production ready horizontal Flux-Free Formic Reflow oven for formic acid vapor soldering. This new oven has been designed to meet Semi S2/S8 safety standards (including toxic gases).

Flux-Free Formic Reflow Oven

• Excellent results demonstrated for wafer bumping application in horizontal reflow oven

• Fluxless reflow utilizes gas phase Formic Acid (HCOOH) to replace standard fluxing agents

• Eliminates the need for pre-reflow fluxing and post-reflow flux cleanup steps

• No post-reflow flux clean facilitates inline application of epoxy and inline epoxy curing solution

Flux-Free Formic Reflow Advantages

• Can use any reflow profile (e.g., tent or soak profile) with formic acid

• Can adjust formic acid profile in oven in conjunction with thermal reflow profile

• Includes Formic acid safety system (i.e., sensors/detectors) adheres to industry standards

|

--ROI-- No need stop production for PM. Easy Maintenance!

|

|

|

--ROI-- No need stop production for PM. Easy Maintenance!

|

Drain Tube with Collection Jar

|

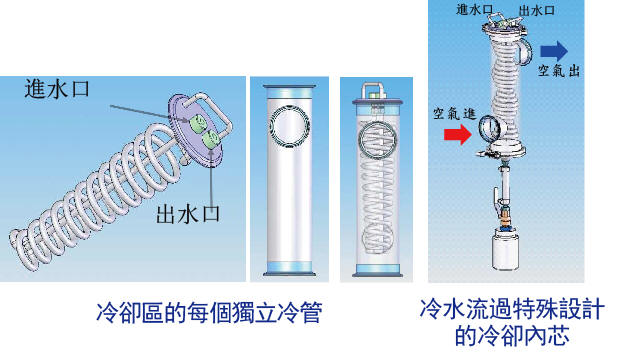

Cooling and Flux Separation System

简易的加热内芯更换及保养